Column

RDcapabilities

13973360936

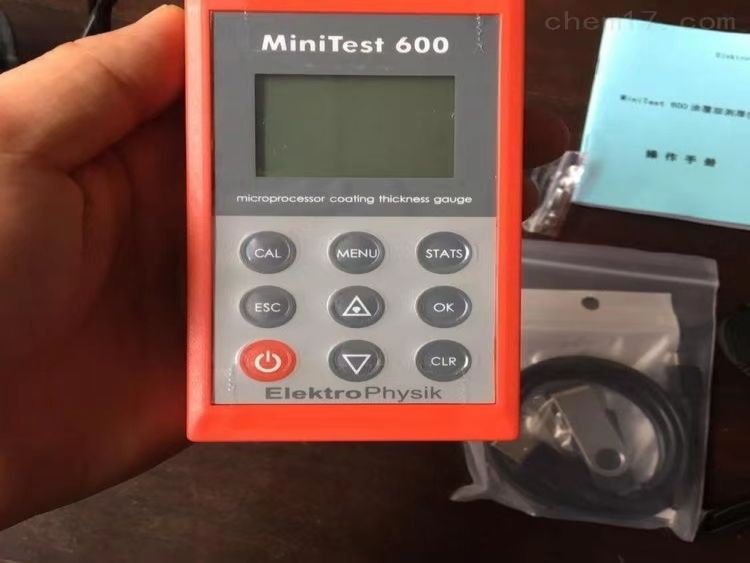

Check for crack or pin-hole, conformance of drawings;

Clean the work piece with acetone to remove oil stain; then dry in the shade;

Spray the surface ruoughness to 32-12.5 if spay with white corundum; not allowed holiday area;

The Pre-heating is to diminish the surface moisture and enhance combination strength, reduce the crack caused by the different coefficient of thermal expansion; the temperature of pre-heat is determined by the size, shape and base-metal of work piece;

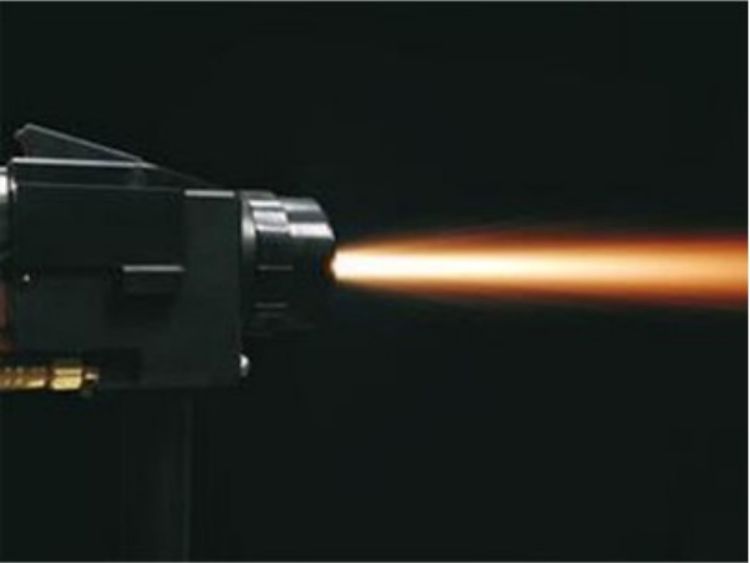

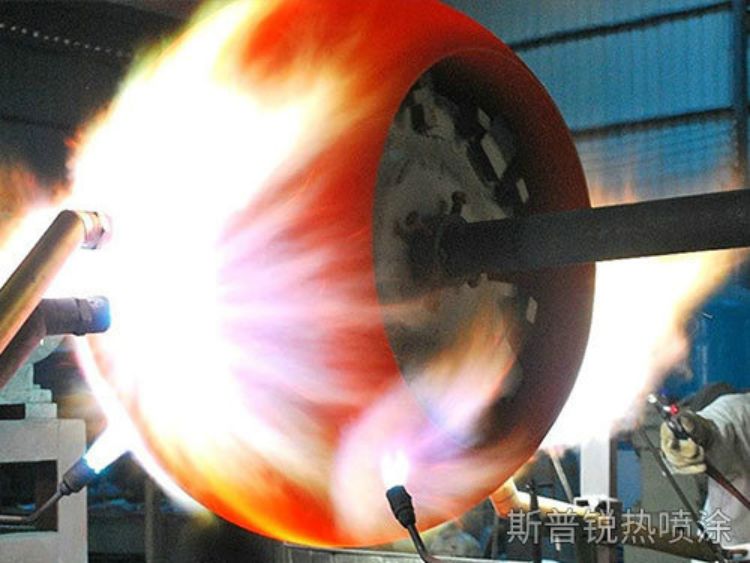

Adopting Suprui P series supersonic coating equipment to process Tungsten carbide powder, the temperature of the work piece is within 200℃ and has very little affect on performance;

The coating material shall be kept in wood box, handle with gentile to avoid impact.

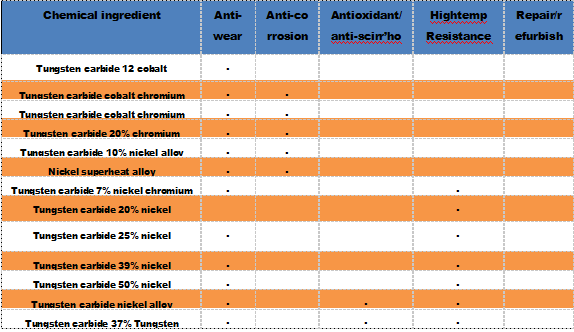

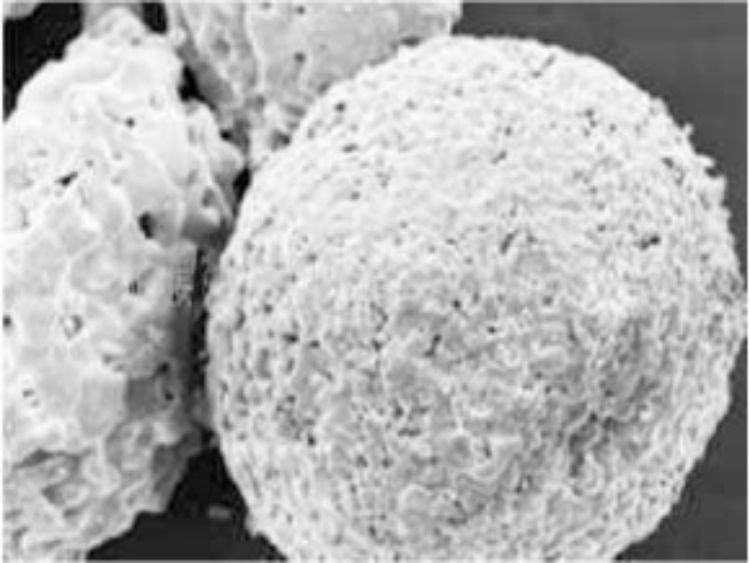

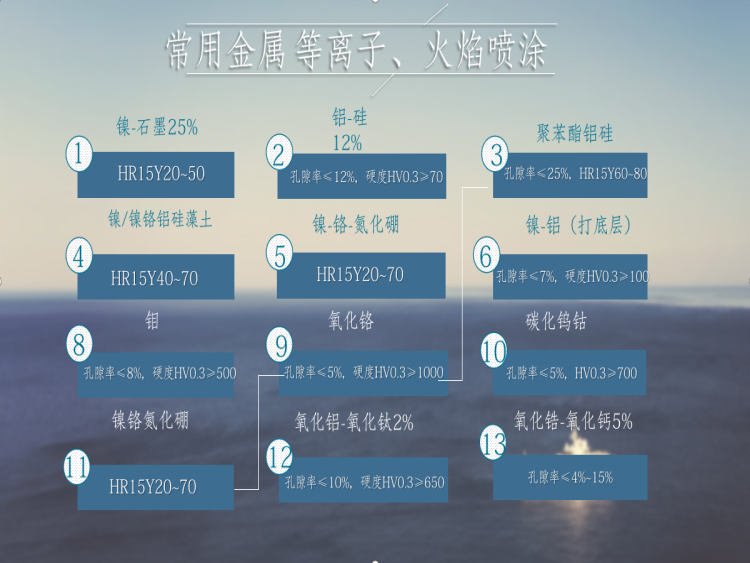

HVo F Material correct material lead to success

The HVoF coating of Zhuzhou S Pu Rui thermal furface coating technology company could reach best performance and conforms to the required size specifications, conforms to HVOF technique. Our specialists will confirm according to different materials and specifications.